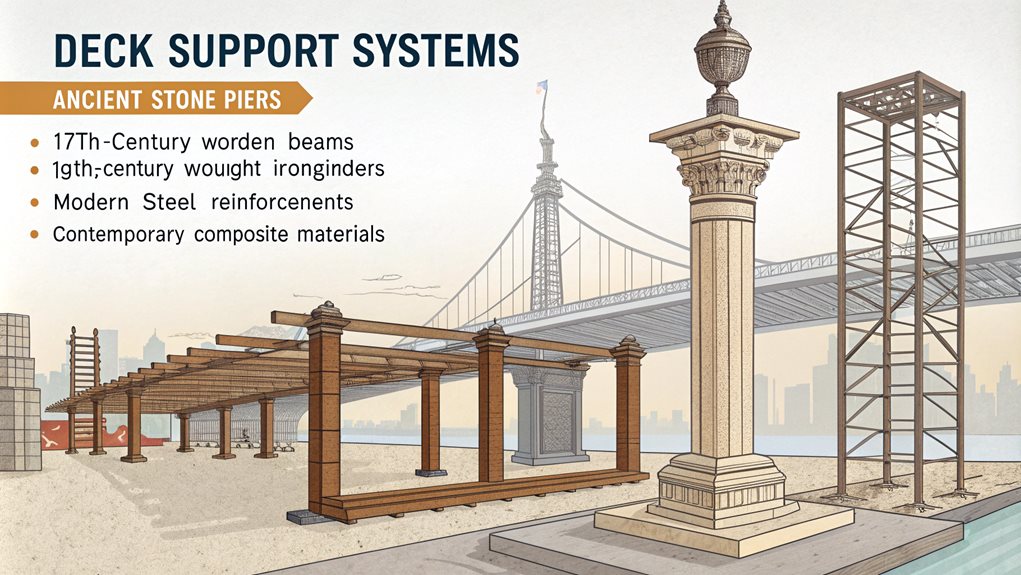

The History of Deck Structural Support Systems

The history of deck structural support systems is rooted in the late 1700s with the introduction of steel decks in England, showcasing early advantages in cotton mills over flammable materials like brick and timber. The Bessemer process of 1855 marked a turning point, enhancing steel strength and durability, influencing structures such as the Crystal Palace. The mid-20th century saw innovations with pressure-treated wood and synthetic materials, leading to more sustainable and diverse designs. Modern techniques like finite element analysis, along with advances in materials like fiber-reinforced polymers, continue to evolve deck construction. Explore these developments to appreciate ongoing innovations.

Expert Highlights

- Early steel deck systems emerged in late 1700s England, initially used in cotton mills and agricultural buildings for economic advantages.

- The Bessemer process, introduced in 1855, revolutionized steel production and facilitated the adoption of steel in construction.

- Mid-20th century saw pressure-treated wood and synthetic materials introducing durability and design versatility in deck construction.

- The evolution of bridge deck types, including truss and girder, highlights the engineering advancement and addresses diverse structural applications.

- Structural analysis techniques like beam analysis and finite element analysis ensure load distribution and safety in deck structural support systems.

Early Steel Deck Systems

In the evolution of architecture, early steel deck systems marked a significant shift towards more resilient and versatile construction solutions. Emerging in the late 1700s in England, these systems were first utilized in cotton mills and agricultural buildings, offering economic advantages and reduced flammability compared to traditional brick and timber. The advent of the Bessemer process in 1855 revolutionized steel production, making high-quality steel widely available and cost-effective. These early innovations set the stage for custom-designed deck developments that seamlessly integrate with architectural styles. Notably, the strength and durability of early wrought iron and riveted steel materials were pivotal in their adoption for construction. Early structures like the Ditherington Flax Mill and Crystal Palace highlighted their structural advantages. Iron and steel frames, typically riveted, supported masonry facades and facilitated long-span applications such as train sheds and exhibition spaces. The rise of industrialized steel building systems in the 20th century further augmented the efficiency and adaptability of steel construction. This era's innovations laid the groundwork for steel's integral role in modern architectural design.

Mid-20th Century Innovations

Amidst the architectural advancements of the mid-20th century, pivotal innovations in deck structural support systems emerged, markedly transforming residential and commercial construction landscapes. The introduction of pressure-treated wood brought significant change by resisting rot, insects, and weathering, thereby allowing for the creation of longer-lasting, durable decks even in adverse climates. This revolutionized deck building, enabling larger and more complex designs. Concurrently, the era saw the rise of synthetic materials and innovative construction methods, broadening the spectrum of design possibilities. Experienced and licensed deck construction professionals incorporated these new materials and techniques into their building practices to ensure safety, durability, and customer satisfaction. With the steel deck's versatility, ease of installation, and material compatibility, construction processes became more streamlined and efficient. Emphasis on sustainable practices saw wider adoption of composite materials, featuring low maintenance and diverse aesthetic options. The emergence of composite decking materials as a sustainable option allowed for reduced environmental impact while maintaining high performance.

Bridge Deck Types

Bridge deck types embody a rich array of material options and design philosophies, each tailored to specific structural and environmental demands. Truss, girder, and arch bridges highlight the evolution of engineering prowess, integrating materials such as steel, concrete, and wood, to address diverse applications and challenges. Advanced design and analysis techniques have further enhanced these structures, ensuring ideal, exemplary, or supreme performance, durability, and safety in modern bridge construction. Furthermore, premium decking materials from leading brands play a crucial role in creating weatherproof and long-lasting outdoor spaces, ensuring that bridges remain resilient in various conditions.

Diverse Material Options

Among the many materials available for constructing bridge decks, each offers distinct advantages and challenges that cater to various engineering needs and environmental considerations.

Concrete remains a prevalent choice due to its adaptability and durability, especially when properly reinforced and protected against corrosion. Its versatility allows for both cast-in-place and precast applications, offering flexibility in construction methods.

Steel, particularly orthotropic and exodermic decks, balances strength with a lighter weight, optimizing support demands and easing installation processes. Composite decks exploit the strengths of concrete and steel, enhancing structural integrity and facilitating recycling opportunities.

Advanced materials such as fiber-reinforced polymers and polymer concrete provide innovative alternatives, emphasizing strength and reduced maintenance. Each material thus plays a crucial role in modern bridge engineering.

Design and Analysis Techniques

In the domain of bridge engineering, design and analysis techniques for bridge decks form the cornerstone of ensuring structural integrity and resilience. Among these techniques, the Approximate Method (Equivalent Strip Method) is foundational, utilizing assumptions that support truck axle loads on transverse strips. This method involves calculation based on equations from AASHTO-LRFD specifications for determining strip width.

Meanwhile, the empirical design method for deck slabs leverages laboratory testing to highlight arching action, requiring less reinforcement for interior sections. Structural analysis techniques, such as Finite Element and Grillage Analysis, further enhance understanding by simulating conditions and evaluating transverse bending moments.

Together, these methods provide a robust framework for analyzing and designing bridge decks, catering to the community's need for safety and stability.

Structural Analysis Techniques

Structural analysis techniques for deck support systems primarily focus on evaluating the performance of beam and grid systems, as well as plate and strip methods, which are critical in understanding load distribution and structural integrity.

Beam and grid analysis typically involves the assessment of beam decks, distributing vertical loads to girders, and grid decks, employing grillage analysis to optimize material use and load transfer efficiency.

Additionally, in creating outdoor living spaces, custom deck design(https://example.com/custom-deck-design) and construction ensure seamless integration and tailored layouts that fit individual project needs.

Conversely, plate and strip methods are often applied to slab decks to account for dual-direction stiffness, employing orthotropic analysis when required, in this manner ensuring that the decks can adequately resist flexure and membrane forces.

Beam and Grid Analysis

Beam and grid analysis represent key components of structural analysis, focusing on understanding the behavior of individual beams and their integration within a grid. This analysis is essential in civil, mechanical, and structural engineering for building resilient structures.

At its core, beam analysis encompasses the determination of critical parameters like reaction forces, shear, bending moments, deflection, and rotational values, leveraging the Euler-Bernoulli beam theory. The goal is to guarantee each beam can carry its load safely.

Key elements in effective beam analysis include:

- Drawing Free Body Diagrams: Illustrating forces and support types.

- Equilibrium Equations: Ensuring forces and moments balance.

- Shear and Bending Moment Calculations: Evaluating internal force distributions.

- Load Categorization and Calculation: Differentiating and determining load impacts, guaranteeing structural safety.

Plate and Strip Methods

Among the diverse techniques in structural analysis, plate and strip methods stand out for their applicability to flat plate systems and specific architectural forms like folded plate structures. These methods, rooted in Reissner's plate theory, adeptly incorporate shear deformation effects, enhancing the accuracy of structural evaluations.

In employing finite strips for plate analysis and utilizing Fourier series expansions for axial direction behavior, the techniques provide a robust framework for analyzing plates over multiple supports, pivotal for complex architectural designs. Especially effective for continuous and folded plate structures, these methods contribute fundamentally to understanding stresses and deflections.

While requiring computational resources, their balanced approach offers efficiency and precision, fostering a sense of inclusion within the engineering community devoted to structural excellence.

Overcoming Initial Challenges

In the nascent stages of deck structural support systems, overcoming initial challenges was pivotal to the industry's evolution. High equipment costs initially deterred smaller companies from entering the steel deck market. Over time, technological advancements and economies of scale reduced these costs, fostering greater diversity and competition. Meanwhile, the growing trend for sustainable hardwood(#) choices in contemporary deck designs provided eco-friendly alternatives for enhanced outdoor spaces. Additionally, the steel deck industry addressed growing energy efficiency concerns by introducing improved designs. These new profiles enhanced both strength and energy performance, leading to broader adoption. The establishment of uniform industry standards by the Steel Deck Institute in 1939 guaranteed consistency and quality. Safety regulations, enforced by organizations such as OSHA, evolved in tandem, safeguarding workers. These advancements collectively transformed the industry, paving the way for future developments:

- Equipment Costs

- Energy Efficiency

- Industry Standards

- Safety Regulations

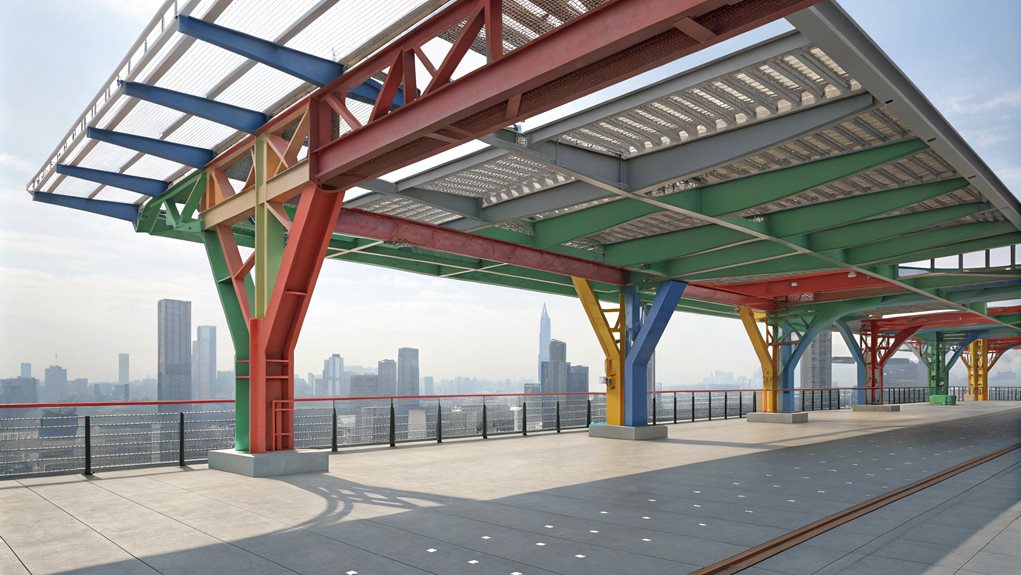

Modern Construction Practices

Modern construction practices in deck structural support systems are defined by innovation and efficiency, reflecting advancements that address both structural demands and aesthetic aspirations. Composite decking combines the strength of steel and concrete, ideal for commercial buildings, offering both durability and fire resistance. Steel decking, with its various profiles, supports substantial loads, guaranteeing compliance with safety standards through its non-combustible nature. Metal floor decking provides temporary but essential support, integrating seamlessly into finished structures to enhance stability. It allows for efficient installation, especially pivotal in seismic areas. Additionally, lighting integration in pergolas offers enhanced functionality, providing a seamless blend of practicality and aesthetics for outdoor living spaces.

| Deck Type | Features | Applications |

|---|---|---|

| Composite Decking | Mechanical bond, fire resistance | Commercial and industrial |

| Steel Decking | Strength-to-weight ratio | Commercial, residential, infrastructure |

| Metal Floor Decking | Temporary support, interlocking design | Construction phase support |

| Design Flexibility | Innovative shapes, finishes for aesthetics | Creative architecture |

These innovations not only guarantee practicality in construction but also support creative architectural designs.

Importance of Safety Standards

Advancements in modern construction practices have set the stage for an increased focus on rigorous safety standards, ensuring that innovative deck structural support systems not only meet aesthetic and functional demands but also adhere to high safety benchmarks. The evolution of these standards reflects a history of prioritizing safety: 1. Early Regulations: Foundational safety standards, initiated by the SDI in 1939, laid the groundwork for safe steel deck usage. 2. Development of Codes: Codes like the first Specifications Code in 1955 have continuously evolved to align with industry demands. 3. Industry Compliance: Adhering to these standards mitigates safety risks, enforcing uniform practices across regions. 4. Technological Advancements: Innovations have enhanced manufacturing and design, aligned with stricter safety requirements, offering industry-wide benefits. Utilizing composite decking materials in porch designs not only enhances durability and aesthetics but also aligns with modern safety standards. Such dedication fosters trust and unity within the construction community.

Future of Deck Systems

The future of deck systems is profoundly shaped by the integration of sustainable materials and advanced technologies. Eco-friendly materials help reduce environmental impact, aligning with global sustainability goals. Recycled composite decking attracts LEED credits, while energy-efficient designs minimize operational costs. Advanced technologies enhance structural resilience and efficiency. Building Information Modeling (BIM) and Artificial Intelligence (AI) optimize design, fostering collaboration and innovation. Real-time structural health monitoring allows predictive maintenance, increasing longevity and safety. Modular and prefabricated methods promise precision and rapid construction, streamlining processes without sacrificing quality. The adoption of seismic-resistant technologies and resilient materials prepares deck systems for extreme weather and climate change, safeguarding structures and reinforcing their role in future community living spaces. Additionally, integrating elements from the expertise in gazebo design and construction industry can further enhance the aesthetics and functionality of outdoor deck spaces, creating cohesive and harmonious living environments.

Deck Building And Design FAQ

Who First Invented the Steel Deck System Before Loucks and Giller?

Before Loucks and Giller, the steel deck system can be traced back to the early innovations by companies and engineers experimenting with steel in structural applications, capitalizing on its strength and durability to enhance construction practices profoundly.

What Were the Earliest Materials Used in Bridge Deck Construction?

The earliest materials used in bridge deck construction were natural elements such as wooden planks, logs, and stones. These reflect humanity's resourcefulness and creativity in shaping environments and connecting communities through practical and enduring architectural solutions.

How Have Environmental Concerns Influenced Steel Deck Development?

Environmental concerns have driven advancements in steel deck development by promoting recyclable materials, enhancing energy efficiency, and optimizing resources. This includes reducing waste, improving seismic and wind resistance, and incorporating innovative technologies for sustainable infrastructure solutions.

What Are the Long-Term Maintenance Requirements for Steel Deck Systems?

Long-term maintenance of steel deck systems involves regular cleaning, corrosion prevention through protective coatings, inspection of mechanical fasteners and insulation, and ensuring debris-free gutters. Proactive care mitigates structural damage and prolongs the system's lifespan and integrity.

Are There Any Emerging Materials Replacing Steel in Deck Support Systems?

Emerging materials, such as composite materials, advanced polymers, aluminum, and fiber-reinforced polymers, are increasingly replacing steel in deck support systems, offering enhanced durability, corrosion resistance, and sustainability, appealing to environmentally conscious communities and industry professionals alike.