What to Consider When Designing Deck Support Systems

When designing deck support systems, it is essential to guarantee structural stability by using appropriate foundation and footings that extend below the local frost line. Consider the soil conditions and distribute loads effectively to prevent structural failure. Substructure components, such as support posts and beams, are integral to maintaining deck strength. Choose weather-resistant hardware and fasteners, like stainless steel, to withstand environmental challenges. Factor in load distribution for safety, and adhere to local codes for compliance. Additionally, climate conditions and material selection impact deck durability and appearance. Discover more nuances that elevate a deck design from just functional to exemplary.

Expert Highlights

- Ensure structural stability by extending footings below the frost line and considering soil conditions.

- Use galvanized or stainless steel hardware for weather resistance and longevity.

- Calculate accurate load distribution, including live and dead loads, for safety and durability.

- Adhere to local codes and regulations to ensure safety and compliance.

- Consider local climate when selecting decking materials for durability and maintenance needs.

Foundation and Footings

When designing a deck, the foundation and footings are pivotal to guaranteeing structural stability and longevity. The depth of footings should extend below the local frost line, preventing movement due to soil freezing and thawing. The frost line varies geographically, typically ranging from 36 to 48 inches, necessitating local building department consultation for precise requirements.

Choosing appropriate footing types, such as poured concrete or buried post and footing, ascertains durability. The choice of materials, such as pressure-treated lumber or composite boards for the deck's construction, also plays a significant role in the overall resilience and integration with the footing design. Deck footings keep the deck elevated above the ground, preventing rot, which is essential for maintaining the structure's integrity over time. Soil conditions heavily influence footing design; clay necessitates wider footings, while gravel may require professional assistance. Proper load distribution is paramount, with footings dispersing deck weight to a broader soil area. It is crucial to prevent structural failure and detachment by ensuring your deck is adequately supported. Typically, spacing footings less than eight feet apart is recommended for ideal stability and support.

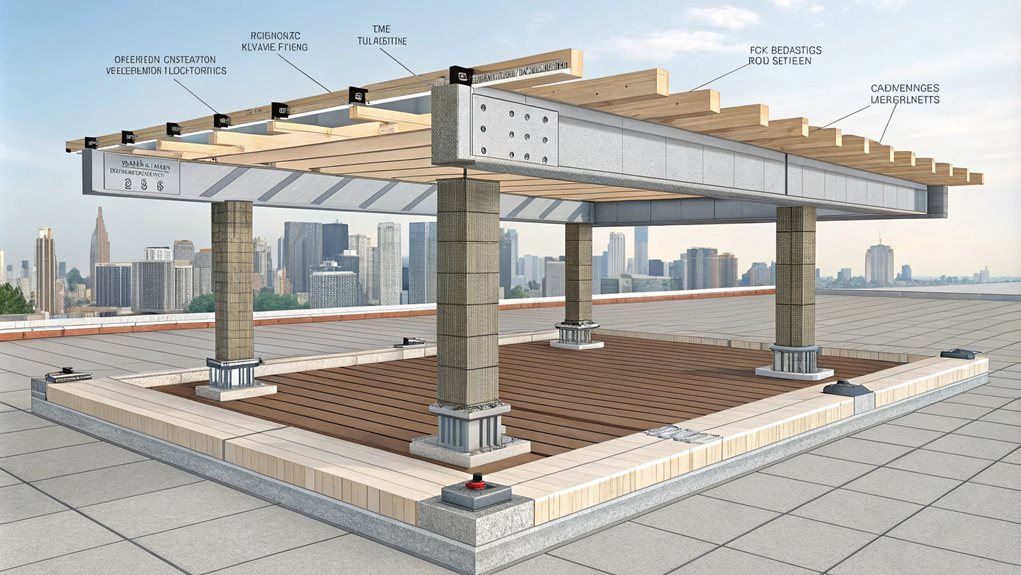

Substructure Components

A deck's substructure is the backbone of its overall stability and integrity, comprising several key components that work in unison. Support posts, crafted from materials like treated wood, steel, or composites, connect the deck to footings, transmitting loads effectively. Beams, or girders, run parallel to the ledger board, providing solid support for deck joists, enhancing durability. Substructure components like floor joists play a vital role in ensuring that the deck can support the weight of people and furniture, while preventing issues like sagging or uneven surfaces. Joists, spaced typically 16 inches apart, support decking boards and maintain structural balance. Composite decking, made from up to 95% recycled and reclaimed content, further contributes to the sustainability and durability of modern deck structures. Blocking prevents joist twisting, bolstering the substructure's stability. Each component plays a pivotal role in ensuring the deck stands firm and sturdy, aligning with the desires for safety and community as well as aesthetic integration with the home.

Hardware and Fasteners

When selecting hardware and fasteners for deck support systems, essential weather-resistant choices are paramount to guarantee longevity and structural integrity. Materials like galvanized or stainless steel are preferred for their ability to resist rust and corrosion, directly influencing the deck's appearance, durability, and overall cost. Deck maintenance and repair services are crucial to prolonging the operational lifespan of your deck, ensuring it remains safe and aesthetically pleasing over time. While hidden fastening systems offer a polished finish and can increase the initial investment, they also enhance the deck's visual appeal by eliminating visible screws, contributing to both aesthetic value and functional resilience.

Essential Weather-Resistant Choices

Selecting the right hardware and fasteners is critical to enhancing your deck's durability and lasting performance in challenging weather conditions. Stainless steel fasteners are highly recommended for their robust corrosion resistance, guaranteeing your deck stays secure in moist environments. Galvanized fasteners provide added protection against rust, ideal for areas prone to dampness.

Weather-resistant screws are essential for maintaining structural integrity amid diverse weather. Self-adhesive flashing tape offers an additional layer of protection, shielding joists and beams from water damage effectively. Utilizing under-deck systems like aluminum and corrugated plastic panels aids in directing water away, preventing moisture buildup. These thoughtful selections guarantee your deck endures harsh climates, promoting a sense of community by being a reliable space for shared gatherings.

Impact on Cost and Appearance

The durability provided by weather-resistant choices extends beyond protecting against the elements; it also influences the financial and aesthetic aspects of your deck. Selecting appropriate hardware and fasteners is essential for balancing cost and appearance. The visibility of fasteners impacts both budget and visual appeal.

Consider these factors:

- Cost Evaluation: Hidden fasteners, while pricier, enhance appearance by creating a seamless look. Budget-friendly options like screws can reduce costs but may sacrifice aesthetics.

- Durability over Cost: High-quality fasteners promise longevity, potentially saving on future maintenance expenses, though they might command a higher upfront investment.

- Aesthetic Harmony: Choosing hardware that complements your deck's design enhances overall cohesion. Matching decorative caps or plugs can obscure fasteners, contributing to an uncluttered, elegant finish.

Load and Weight Distribution

Understanding load and weight distribution is essential in designing a reliable and durable deck support system. The deck must accommodate various loads, including live, dead, point, and distributed loads, each contributing differently to overall stress. Incorporating materials with natural resistance to rot, such as cedar, enhances the durability and longevity of the deck structure.

| Load Type | Description | Measurement |

|---|---|---|

| Live Load | Temporary moving loads (people, furniture) | 40 PSF for residential decks |

| Dead Load | Permanent structure weight | 10-15 PSF |

| Point Load | Load concentrated on a small area | Pounds or kilograms |

| Distributed Load | Spread over the entire deck surface | Pound per square foot (PSF) |

| Dynamic Loads | Stress from activities like jumping | Varies |

Accurate load distribution involves calculating the deck's capacity, guided by structural design, materials, and safety compliance. Consulting professionals can guarantee safety and durability.

Integration With House and Yard

When conceptualizing a deck, one's primary aim should be its seamless integration with both the house architecture and the surrounding yard landscape. This guarantees the deck is not only functional but also aesthetically pleasing, blending into its environment harmoniously.

To achieve this, attention should be paid to:

- Architectural Alignment: Align the deck's entry points with the home's doorways, using complementary materials and colors that match the house's style and era. This ascertains a unified look.

- Landscape Harmony: Design the deck to fit naturally within the yard's size and shape, considering elements like existing gardens and sun patterns to enhance usability and visual appeal.

- Functional Design Balance: Create multifunctional spaces on the deck, perhaps incorporating built-in planters and smart technologies for added convenience and enjoyment.

A well-designed deck can create a harmonious outdoor living space, facilitating seamless interaction between your indoor and outdoor environments.

Climate and Environmental Factors

Considering the diverse array of climate and environmental factors is pivotal in the design and construction of effective deck support systems. In wet and rainy climates, composite decking offers moisture resistance, reducing mold risks, while proper drainage avoids water buildup. Pressure-treated wood choices add protection against rot in humid areas. Contrastingly, in dry and hot climates, composite materials prevent warping, and lighter colors reflect sunlight, minimizing heat. Wood here benefits from UV-protective finishes. For snowy regions, composite decking simplifies snow removal, with steel framing enduring temperature changes. High wind conditions necessitate composite durability up to 110 mph, and steel provides stability. Recognizing these climate-specific strategies fosters a reliable, lasting, and cohesive deck design, enhancing community ties through shared environmental resilience. Experienced pergola contractors can also offer insights on customizing outdoor structures to withstand diverse weather conditions.

Compliance With Local Codes

Adherence to local codes is essential in guaranteeing that deck support systems meet both safety and regulatory standards. These codes, influenced by the International Residential Code (IRC), can vary considerably due to regional factors, such as unique climate conditions or local materials. To align with these requirements, consider the following:

- Contact Local Authorities: Always reach out to the local building department for the most updated information and to obtain necessary permits.

- Consult Professionals: Engage architects and contractors well-versed in local codes for expert advice and to avoid common pitfalls, like improper ledger installation.

- Review Code Resources: Utilize available online resources to ascertain you are aware of both general and specific code requirements to avoid confusion with older structures.

For specialized installations, such as a minimalist deck with clean lines, ensure adaptation of precise and intentional design elements to maintain both aesthetic quality and structural stability.

Deck Building And Design FAQ

How Do I Choose the Best Materials for Deck Support in My Region?

To select ideal deck support materials, evaluate regional climate impacts, including sun, snow, humidity, and wind. Guarantee compliance with local building codes, prioritize durability for structural integrity, consider aesthetic cohesion with surroundings, and factor in cost and local availability.

What Maintenance Is Required for Deck Support Systems After Installation?

To maintain deck support systems post-installation, conduct annual inspections for structural integrity, guarantee proper flashing to prevent moisture, clean debris regularly, tighten fasteners, and replace corroded components to secure the longevity and safety of your deck.

Can I Modify My Existing Deck Support System for a Pergola Addition?

Modifying your existing deck support system for a pergola is feasible if structural integrity is guaranteed. Assess and reinforce foundations, beams, and ledger boards. Comply with local codes and prioritize safety, aesthetics, and functionality for community harmony.

How Can I Incorporate Eco-Friendly Practices Into My Deck Design?

Incorporating eco-friendly practices into deck design involves utilizing sustainable materials such as FSC-certified wood or recycled composites, integrating green features like drought-tolerant plants, and maintaining eco-conscious construction standards to minimize environmental impact, reduce waste, and conserve resources.

What Are the Common Signs of Failing Deck Support Systems?

Common signs of failing deck support systems include loose and unstable railings, corroded fasteners, rotting or waterlogged joists, cracked footings, spongy deck boards, and detached or improperly fastened ledgers, indicating overall structural weakness and potential safety hazards.