What to Know About Deck Load-Bearing Requirements

Understanding deck load-bearing requirements is essential for safety and compliance. Gravity loads involve dead loads from the deck structure, typically 10 psf, and live loads from occupants and furnishings, at least 40 psf. Snow loads must be considered in heavy winter areas. Lateral loads from wind and seismic activity require appropriate anchoring and fastening, while factors like soil settlement affect stability. Utilizing high-grade materials and corrosion-resistant fasteners guarantees longevity. Compliance with local building codes and human activities impact load distribution. Properly designed footings and ledger connections are critical for load transfer, enhancing deck stability with effective beam placement. Explore further details for thorough insights.

Expert Highlights

- Gravity loads include dead loads (deck structure weight) and live loads (occupants and furnishings), with minimum requirements typically 10 psf and 40 psf, respectively.

- Lateral loads originate from wind, soil settlement, seismic activity, and human activities, requiring strong ledger connections and proper bracing.

- Use high-grade lumber and corrosion-resistant fasteners to ensure durability against gravity and lateral loads.

- Compliance with local building codes and the IRC is essential for appropriate deck design and load-bearing capacity.

- Personalized deck layouts optimize beam placement for stability and effective load distribution.

Understanding Gravity Loads

Understanding gravity loads is fundamental to ensuring the structural integrity of a deck. Gravity loads, composed of dead and live loads, represent the primary forces acting upon a deck, impacting design and safety.

Dead loads, a constant factor, include the inherent weight of the deck's structural elements—decking materials, joists, beams, and accessories like railings—typically amounting to 10 psf. Live loads, varying with usage, encompass the weight of occupants and furnishings, with a minimum requirement of 40 psf, as stipulated by the IRC. It is important to account for additional factors such as snow load in regions with heavy winter weather, as snow load can significantly increase the burden on the deck, requiring further consideration and adjustments to the design. Given these dynamics, the deck's supporting components—such as footings and ledger connections—play crucial roles in distributing gravity loads effectively to maintain stability. Cedar's natural resistance to environmental factors, such as rot and insect damage, adds to the structural reliability of the deck.

Total design loads, the sum of these, generally reach 50 psf for residential decks. Ensuring an even load distribution across joists and beams is essential. Adhering to local building codes reinforces the community's shared commitment to safety and durability.

Mitigating Lateral Loads

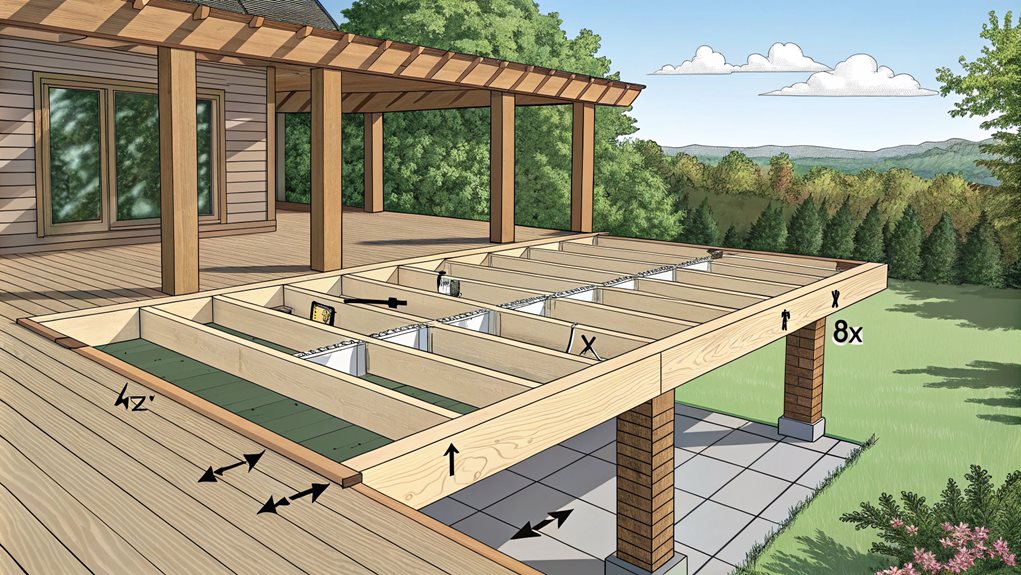

Mitigating lateral loads in deck construction requires thorough understanding of various forces, including wind, soil settlement, and seismic activity, that can affect structural stability. Essential elements of deck weight capacity, such as beam and joist spacing, directly influence the deck's ability to withstand lateral forces. Adhering to seismic connection guidelines and incorporating design elements such as knee braces, proper ledger connections, and additional support can effectively resist these forces. Employing methods like bracing and using appropriate fasteners, while consulting both the International Residential Code and local amendments, guarantees extensive load resistance and compliance with safety standards. For additional structural integrity, integrating personalized deck layouts can help in optimizing beam placement for better weight distribution and overall stability.

Sources of Lateral Loads

Lateral loads pose significant challenges when designing and constructing a deck, necessitating robust strategies for mitigation. Wind forces, particularly in high-exposure areas, push decks horizontally, making anchoring indispensable. Differential settlement of soil results in uneven support, compelling proper footing design to guarantee stability. Seasonal changes in wood components cause swelling, shrinking, or twisting, demanding the use of proper fasteners and connectors that accommodate movement. Human activities such as dancing exert lateral forces, necessitating strong ledger connections. For example, lag screws used in ledger boards must be at least 1/2" in diameter and go through the band board for adequate support. Compliance with local building codes and the International Residential Code (IRC) for permitted connection methods is essential. Routine inspections and maintenance of all connections and footings confirm sustained deck stability, addressing these various lateral load sources effectively.

Seismic Connection Guidelines

Proper seismic connection guidelines are essential for ensuring deck stability in earthquake-prone areas. Establishing these guidelines involves detailed seismic load calculations, considering factors like deck mass, acceleration, site class, and seismic zone. The American Society of Civil Engineers (ASCE 7-10) equivalent lateral force procedure helps determine maximum ASD-factored seismic loads, which might be up to 1,250 lb for a 12 ft by 12 ft deck.

| Seismic Zone | Ss (Ground Acceleration) | Lateral Force (F) |

|---|---|---|

| High Risk | ≥ 1.5g | 517 lb |

| Medium Risk | 1.0g | 379 lb |

Hold-down requirements vary, yet usually necessities include two devices with at least 1,500 lb capacity each. However, specific conditions may permit reduced capacities, ensuring robust lateral displacement resistance.

Methods for Load Resistance

In the domain of deck construction, guaranteeing the stability against lateral loads is a pivotal concern. Proper ledger connections are fundamental, as outlined by the IRC, mandating either two 1500 lbs or four 750 lbs connections to secure deck joists to the house's structure.

Posts over 4 feet high necessitate knee braces, while adequately sized footings with reinforcement bars provide essential resistance against lateral forces. For joist and beam configurations, closer spacing and proper blocking or bridging are essential.

Additionally, diagonal bracing and regular maintenance, including using corrosion-resistant hardware, fortify the deck against displacement or swaying. Compliance with these measures guarantees community members' decks remain stable and safe against lateral loading challenges.

Choosing Deck Materials

Selecting suitable deck materials is essential for ensuring the durability and safety of your outdoor structure. Choose high-grade lumber, such as "select structural" or No. 1 & better, to enhance structural integrity. Inferior grades can lead to increased installation time and suboptimal results, nullifying cost savings. Redwood labeled "Construction heart" provides reliable quality.

Solid design specifications are indispensable; they determine the size and spacing of footings, beams, and joists, distributing loads effectively, especially with features like hot tubs. Utilize corrosion-resistant fasteners, like hot-dipped zinc-coated galvanized steel or stainless steel, adhering to manufacturer's guidance for ideal load paths. Consistency in materials avoids corrosion issues, securing a dependable structure. These considerations foster a robust, long-lasting deck, contributing to a safe, shared outdoor environment. Consider how your personal style integration can seamlessly blend the deck with your home's architecture to create an inviting extension of your living space.

Navigating Building Codes

Traversing building codes is an essential aspect of deck construction, beginning with understanding local amendments that might affect safety and compliance requirements. Obtaining the appropriate permits is pivotal, as these documents guarantee that your design adheres to local standards and regulations. Regular inspections throughout the construction process not only confirm compliance but also help identify any issues that could impact the structural integrity and safety of the deck. Incorporating comprehensive deck material selection ensures your deck meets durability and safety expectations while aligning with local regulations.

Understanding Local Amendments

Compliance with local building codes is essential for ensuring the safety and stability of a deck. Understanding the specific amendments within your jurisdiction is vital. Local code variations often differ from national standards, like the International Residential Code (IRC).

For instance, Washington State amendments mandate a live load of 60 psf instead of the usual 40 psf. These codes take into account regional factors such as snow load, wind exposure, and soil conditions, indispensable for safety. Local building departments provide specific code requirements, including adjustments for snow-prone areas and high wind zones.

Footing sizes, lumber spans, and ledger board attachments can also be subject to local regulations. Ensuring compliance with these codes fosters a sense of belonging within a community committed to safety.

Obtaining Permits and Inspections

Securing the necessary permits and undergoing thorough inspections are critical steps in deck construction. For decks that are more than 10 feet above ground or designed to support weighty items like hot tubs, permits are generally mandatory.

Local jurisdictions outline specific requirements, which often demand detailed design specifications, including footing dimensions and materials. Inspections occur at pivotal stages, particularly after footing excavation and before framing begins.

Aligning your plans with the International Residential Code (IRC) and respective local amendments is essential. This includes adhering to minimum load requirements and corrosion-resistant fasteners. Regular inspections guarantee compliance with these standards, affirming structural integrity.

Proper documentation and submission of plans, as well as approvals for any changes, are necessary to finalize construction smoothly.

Enhancing Load Capacity

To enhance the load capacity of a deck, it is vital to focus on reinforcing key structural components and optimizing the overall design. Adding extra support posts and footings can promptly decrease beam and joist spans, effectively increasing the deck's load-bearing capacity. Sistering new joists or beams along existing ones, and bolting steel plates to structural elements, further fortifies the load capacity. Correct connections to the house framing, possibly using hold-down devices, are vital for stability. Additionally, optimizing deck design involves specifying proper spacing for footings and using high-grade lumber to guarantee even load distribution. Considering both live and dead loads during the design phase adds to the structural integrity, aligning with local building code requirements for safety under various conditions. To address specific terrain challenges, a multi-level deck design can be implemented, allowing for effective load distribution and enhanced accessibility.

Designing Footings and Foundations

Enhancing the load capacity of a deck underscores the importance of a well-designed footing and foundation system. Footings must be adequately sized to manage both dead and live loads, with a minimum soil bearing capacity of 2000 psf, guaranteeing they are deep enough to reach stable ground. Material selection is critical; concrete should have a compressive strength of at least 2500 psi, with deck lumber being #2 Southern Pine or better. Proper load distribution is essential for reinforcing structural integrity, particularly in areas with heavy appliances. Regional environmental factors like snowfall and wind necessitate larger and more durable foundations. Compliance with local building codes verifies safety and functional adherence, addressing soil types and slopes, to build a resilient, unified deck structure. A well-designed porch can serve as the focal point of a home, enhancing curb appeal and providing a welcoming outdoor retreat.

Deck Building And Design FAQ

How Do Seasonal Weather Changes Affect Deck Maintenance?

Seasonal weather changes necessitate proactive deck maintenance, including regular inspections and protective measures such as waterproofing, proper drainage, and ensuring solid structural design to withstand moisture, temperature fluctuations, snow, ice, wind, and seismic forces effectively.

What Precautions Should Be Taken for Decks Near Coastal Areas?

When constructing coastal decks, prioritize robust framing, secure bracing, and corrosion-resistant materials to withstand heavy loads, strong winds, and environmental elements. Regular inspections guarantee resilience, fostering a shared commitment to safety and durability within coastal communities.

How Does Landscaping Impact Deck Load-Bearing Requirements?

Landscaping markedly influences deck load-bearing requirements by altering soil stability, affecting drainage, introducing additional loads from heavy decor, and necessitating compliance with building codes. Careful planning guarantees structural integrity and harmony with surrounding environments for community integration.

Can Lighting Installations Affect a Deck's Structural Integrity?

Lighting installations can greatly impact a deck's structural integrity by increasing the dead load. Proper installation and even load distribution are essential, while adherence to local building codes guarantees safety and compatibility with the deck's design capacity.

What Role Do Innovative Technologies Play in Modern Deck Construction?

Innovative technologies enhance modern deck construction by improving durability, safety, and aesthetic appeal. Advanced materials and fastening systems, combined with engineering tools and enhanced techniques, result in structurally robust, low-maintenance decks that meet both functional and regulatory standards.