Polystyrene

**History and Discovery:**

– Polystyrene discovered in 1839 by Eduard Simon.

– Formation of meta styrol identified in 1866.

– IG Farben began manufacturing polystyrene in 1931.

– Styrofoam patented in 1944.

**Chemical Structure and Production:**

– Polystyrene is a lightweight material with a chemical formula of C8H8.

– Produced as an addition polymer from styrene monomers.

– Homopolymer with a molar mass of 100,000–400,000g/mol.

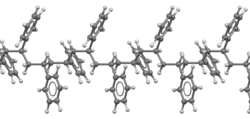

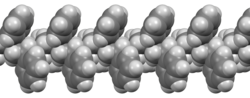

– Polymerization forms carbon-carbon σ bonds, with tetrahedral geometry in the backbone.

**Properties and Applications:**

– Polystyrene can be solid or foamed, transparent, and colored.

– Used widely in packaging, containers, and disposable cutlery.

– Becomes rigid when cooled and is not biodegradable under ASTM standards.

– Applications include protective packaging, containers, lids, bottles, and more.

**Tacticity and Degradation:**

– Tacticity in polystyrene affects properties.

– Atactic polystyrene is standard, while isotactic is not produced commercially.

– Polystyrene is resistant to many acids and bases but easily attacked by organic solvents.

– Depolymerization into styrene by pyrolysis, with commercial recycling back to styrene challenging.

**Environmental Impact and Recycling:**

– Polystyrene is considered non-biodegradable but can be digested by mealworms and superworms.

– Mealworm droppings are safe for soil use, aided by bacterial genera in superworms’ gut.

– Styrene oil from pyrolysis can be converted to biodegradable plastic.

– Polystyrene commonly injection molded, vacuum formed, or extruded, with expanded polystyrene used for protective packaging.

Polystyrene (PS) /ˌpɒliˈstaɪriːn/ is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a poor barrier to air and water vapor and has a relatively low melting point. Polystyrene is one of the most widely used plastics, with the scale of its production being several million tonnes per year. Polystyrene is naturally transparent, but can be colored with colorants. Uses include protective packaging (such as packing peanuts and in the jewel cases used for storage of optical discs such as CDs and occasionally DVDs), containers, lids, bottles, trays, tumblers, disposable cutlery, in the making of models, and as an alternative material for phonograph records.

| |

| |

| |

| Names | |

|---|---|

| IUPAC name

Poly(1-phenylethylene)

| |

| Other names

Thermocol

| |

| Identifiers | |

| Abbreviations | PS |

| ChemSpider |

|

| ECHA InfoCard | 100.105.519 |

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C8H8)n | |

| Density | 0.96–1.05 g/cm3 |

| Melting point | ~ 240 °C (464 °F; 513 K) for isotactic polystyrene |

| Boiling point | 430 °C (806 °F; 703 K) and depolymerizes |

| Insoluble | |

| Solubility | Soluble in benzene, carbon disulfide, chlorinated aliphatic hydrocarbons, chloroform, cyclohexanone, dioxane, ethyl acetate, ethylbenzene, MEK, NMP, THF |

| Thermal conductivity | 0.033 W/(m·K) (foam, ρ 0.05 g/cm3) |

Refractive index (nD)

|

1.6; dielectric constant 2.6 (1 kHz – 1 GHz) |

| Related compounds | |

Related compounds

|

Styrene (monomer) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature. It becomes rigid again when cooled. This temperature behaviour is exploited for extrusion (as in Styrofoam) and also for molding and vacuum forming, since it can be cast into molds with fine detail. The temperatures behavior can be controlled by photocrosslinking.

Under ASTM standards, polystyrene is regarded as not biodegradable. It is accumulating as a form of litter in the outside environment, particularly along shores and waterways, especially in its foam form, and in the Pacific Ocean.