Polyethylene terephthalate

– Names:

– IUPAC name: poly(ethylene terephthalate)

– Systematic IUPAC name: poly(oxyethyleneoxyterephthaloyl)

– Other names: Terylene (trademark); Dacron (trademark)

– Abbreviations: PET, PETE

– CAS Number: 25038-59-9

– Identifiers:

– ChEBI: CHEBI:53259

– ChemSpider: None

– ECHA InfoCard: 100.121.858

– UNII: 5YSH70HE6K

– CompTox Dashboard (EPA): DTXSID10872790

– Properties:

– Chemical formula

– Molar mass: 10–50kg/mol, varies

– Density: 1.38g/cm (amorphous), 1.370g/cm (20°C), 1.455g/cm (single crystal)

– Melting point: 250°C (482°F; 523K), 260°C

– Boiling point: 350°C (662°)

– Uses:

– Packaging: bottles, containers

– Textiles: clothing, upholstery

– Engineering: automotive parts, industrial applications

– Medical: implants, devices

– Recycling: widely recycled for new PET products

– Environmental Impact:

– Recyclability: highly recyclable

– Sustainability: can be recycled into new products

– Energy consumption: lower compared to other plastics

– Carbon footprint: lower greenhouse gas emissions

– Concerns: microplastics, landfill waste

Polyethylene terephthalate (or poly(ethylene terephthalate), PET, PETE, or the obsolete PETP or PET-P), is the most common thermoplastic polymer resin of the polyester family and is used in fibres for clothing, containers for liquids and foods, and thermoforming for manufacturing, and in combination with glass fibre for engineering resins.

| |

| |

| |

| Names | |

|---|---|

| IUPAC name

poly(ethylene terephthalate)

| |

| Systematic IUPAC name

poly(oxyethyleneoxyterephthaloyl) | |

| Other names

Terylene (trademark);

Dacron (trademark).

| |

| Identifiers | |

| Abbreviations | PET, PETE |

| ChEBI | |

| ChemSpider |

|

| ECHA InfoCard | 100.121.858 |

| UNII | |

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C10H8O4)n | |

| Molar mass | 10–50 kg/mol, varies |

| Density |

|

| Melting point | > 250 °C (482 °F; 523 K) 260 °C |

| Boiling point | > 350 °C (662 °F; 623 K) (decomposes) |

| Practically insoluble | |

| log P | 0.94540 |

| Thermal conductivity | 0.15 to 0.24 W/(m·K) |

Refractive index (nD)

|

1.57–1.58, 1.5750 |

| Thermochemistry | |

Heat capacity (C)

|

1.0 kJ/(kg·K) |

| Related compounds | |

Related Monomers

|

Terephthalic acid Ethylene glycol |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

In 2016, annual production of PET was 56 million tons. The biggest application is in fibres (in excess of 60%), with bottle production accounting for about 30% of global demand. In the context of textile applications, PET is referred to by its common name, polyester, whereas the acronym PET is generally used in relation to packaging.[citation needed] Polyester makes up about 18% of world polymer production and is the fourth-most-produced polymer after polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC).[citation needed]

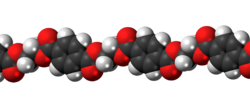

PET consists of repeating (C10H8O4) units. PET is commonly recycled, and has the digit 1 (♳) as its resin identification code (RIC). The National Association for PET Container Resources (NAPCOR) defines PET as: "Polyethylene terephthalate items referenced are derived from terephthalic acid (or dimethyl terephthalate) and mono ethylene glycol, wherein the sum of terephthalic acid (or dimethyl terephthalate) and mono ethylene glycol reacted constitutes at least 90 percent of the mass of monomer reacted to form the polymer, and must exhibit a melting peak temperature between 225 °C and 255 °C, as identified during the second thermal scan in procedure 10.1 in ASTM D3418, when heating the sample at a rate of 10 °C/minute."

Depending on its processing and thermal history, polyethylene terephthalate may exist both as an amorphous (transparent) and as a semi-crystalline polymer. The semicrystalline material might appear transparent (particle size less than 500 nm) or opaque and white (particle size up to a few micrometers) depending on its crystal structure and particle size.

One process for making PET uses bis(2-hydroxyethyl) terephthalate,[citation needed] which can be synthesized by the esterification reaction between terephthalic acid and ethylene glycol with water as a byproduct (this is also known as a condensation reaction), or by transesterification reaction between ethylene glycol and dimethyl terephthalate (DMT) with methanol as a byproduct. Polymerization is through a polycondensation reaction of the monomers (done immediately after esterification/transesterification) with water as the byproduct.

| Young's modulus, E | 2800–3100 MPa |

| Tensile strength, σt | 55–75 MPa |

| Elastic limit | 50–150% |

| Notch test | 3.6 kJ/m2 |

| Glass transition temperature, Tg | 67–81 °C |

| Vicat B | 82 °C |

| Linear expansion coefficient, α | 7×10−5 K−1 |

| Water absorption (ASTM) | 0.16 |

| Source | |

|---|---|